HVOF Thermal Spray Powder Tungsten Carbide WC-15Ni(WC/Ni 85/15)

| Grade |

T.C |

Ni |

Fe |

O |

Process |

| BD-10503 |

5.0-5.4 |

14.5-15.5 |

≤0.2 |

≤0.15 |

Agglomerated & Sintered |

| Particle Size Micron |

Apparent Density g/cm3 |

Hall Flow S/50g |

Appearance |

| 53-20 |

4.3-5.2 |

≤25.0 |

Spherical |

| 45-15 |

| 45-11 |

| 38-10 |

| 25-5 |

| PS: Can be customized according to customer specific requirements |

Physical Properties:Character:High wear resistance, corrosion resistance and high temperature properties.

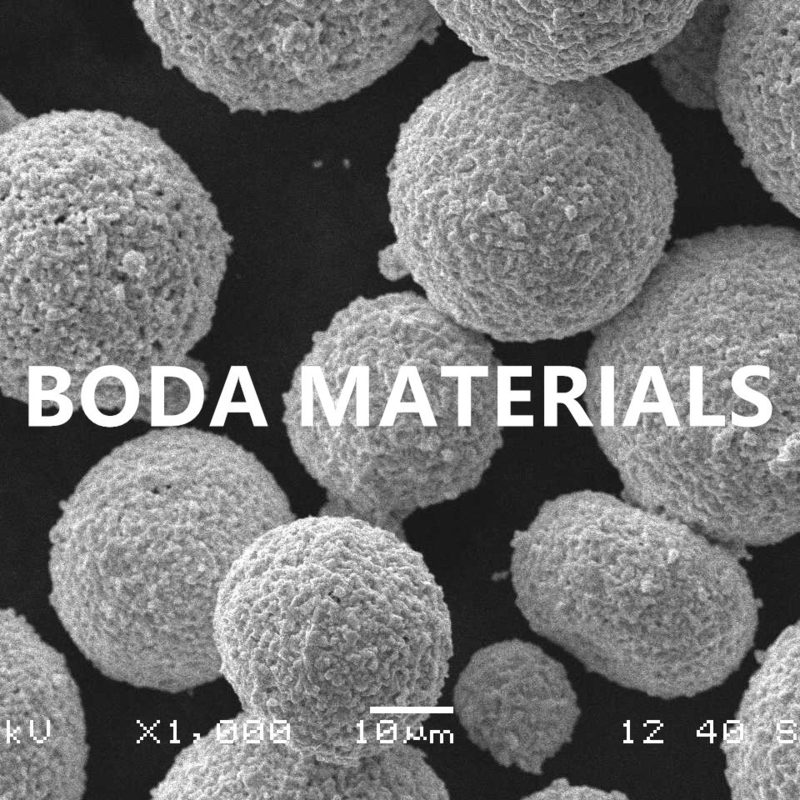

Appearance:Dark gray or metal-luster powder(Spherical)

Particle sizes:45-15um,53-20um,38-10um etc

Size are available by specific requirement.

Introduction:

WC/15Ni is often used in thermal surfacing techniques for its high-wear resistance, perfect corrosion resistance, and high-temperature resistance.

Tungsten Carbide/Nickel Powder (WC/15Ni Powder) is a metal-ceramic- (cermet) composite material used as high-temperature wear and corrosion-resistant coating. The alloyed form gives superior hardness.

Tungsten Carbide/Nickel powder can be used in various industries, including:

-thermal surfacing techniques, such as powder welding, flame spraying, plasma spraying, HVOF (high-velocity oxy-fuel)

-producing wear-resistant parts and components of the feed screw, aero-engine, fan blade, turbine blade, pump case, and cutting tools, etc.

-oil exploit, aerospace, mine excavation, machinery tools, marine facilities, and other fields

Boda HVOF Thermal Spray Powder Products ranges:

| Product |

Particle Size |

Equal to |

Main Performance |

Spray Process |

Applications |

| WC-10Co-4Cr |

45-15um |

Woka 3651 3652

3653 3654

3655 3665 |

Corrosive wear resistance |

HVOF,HVAF,

Atmospheric Plasma

|

Landing gears |

| 45-11um |

Paper manufactureing rolls,Corrugating rollers |

| 38-10um |

Ball,gate and dump valves |

| 25-5um |

Hydroturbine buckets |

| WC-12Co |

53-20um |

Woka 3101, Woka 3102, Woka 3103,

Woka 3105, |

Wear resistance |

HVOF,HVAF,

Atmospheric Plasma

|

Steel rolls |

| 45-15um |

Corrugating rollers |

| 38-10um |

Sucker rod couplings |

| 25-5um |

Conveyor screws |

| WC-17Co |

53-20um |

Woka 3201 3202

3203 3205 3208 |

Ductile Wear resistance |

HVOF,HVAF,

Atmospheric Plasma

|

Landing gears |

| 45-15um |

Pump seals |

| 38-10um |

Exhaust fans |

| 25-5um |

Crushing rollers |

| WC-10Ni |

53-20um |

Woka 3301 3302 3303 3304 3305 |

excellent corrosion resistance,

abrasion and sliding wear

|

HVOF,Plasma spray |

ball valves,gate valves,oil field equipment |

| 45-15um |

| 38-10um |

radio-active environments |

| WC-12Ni |

45-20um |

Woka 3402 3403 3404 3406 |

excellent corrosion resistance,

abrasion and sliding wear

|

HVOF,Plasma spray |

Steeling making |

| 45-15um |

Centrifugal Casting |

| 38-10um |

Plastic centrifuge |

| WC-15Ni |

53-20um |

N/M |

excellent corrosion resistance,

abrasion and sliding wear

|

HVOF,Plasma spray |

Steeling making |

| 45-15um |

Centrifugal Casting |

| 38-10um |

Plastic centrifuge |

| WC-20Cr3C-7Ni |

53-20um |

Woka 3701 3702 3702-1 3703 |

excellent oxidation resistance , good erosion,abrasion wear resistance; |

HVOF,Plasma spray |

iron&steel industry, paper making,pump and valve |

| 45-15um |

field of Screw drilling tools |

| 38-10um |

chemical equipment in petroleum machinery |

| 25NiCr-Cr3C2 |

53-20um |

Woka 7201 7202 7203 7204 7205 7210 |

Excellent sliding,abrasion,

erosion/Corrosion,wear resistance,

Good cavitation,corrosion resistance.

|

HVOF,HVAF,

Atmospheric Plasma

|

Gas turbine |

| 45-15um |

aircraft engine,valve rod,powder generation boiler |

| 38-10um |

metallurgical furnace roller and hydraulic valve etc |

| 20NiCr-Cr3C2 |

53-20um |

Woka 7101 7102 7103 7104 7105 |

Excellent sliding,abrasion,

erosion/Corrisionwear resistance,

Good cavitation,corrosion resistance.

|

HVOF,HVAF,

Atmospheric Plasma

|

Gas turbine |

| 45-15um |

aircraft engine,valve rod,powder generation boiler |

| 38-10um |

metallurgical furnace roller and hydraulic valve etc |

Our Factory and Lab

Advantages:

1.100% factory manufacturing and factory direct sales.

2. Competitive price and quality guarantee.

3.Trial order and customized testing sample are welcomed.

4.Independent research and development ability and high efficient production capacity.

5.We have more than 10 years of experience in producing Thermal spray powder,tungsten carbide materials,PTA,Metal Caride.

6.We have through the ISO9001 quality management system certification.

7.We have a professional team and engineer, can solve all the problems you meet .

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!