Product Description:

| W |

Ct |

Fe |

Ni |

Cr |

B |

Si |

C |

Fe |

Blend Ratio (Wt %) |

| Balance |

3.8-4.1 |

<0.5 |

Balance |

6.5-7.5 |

2.5-3.3 |

4.0-5.0 |

<0.06 |

<5.0 |

60:40 |

| Particle Size |

Hardness (CTC)HV0.1 |

Matrix Hardness (HRC) |

Apparent Density (g/cm3) |

| 120-325mesh |

-125+45um |

2000-2200 |

60 |

6.5-7.5 |

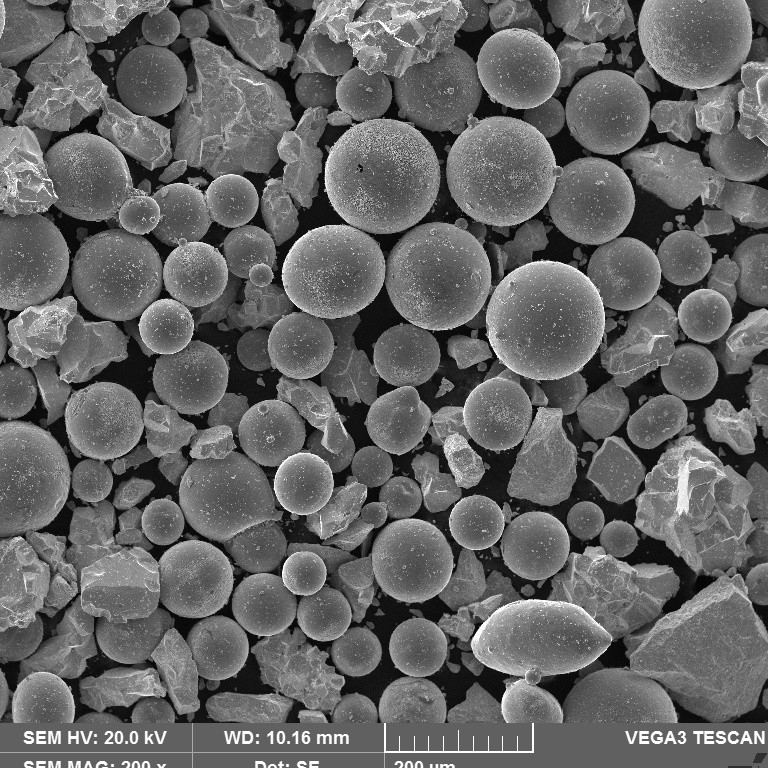

PE1229 is a type of metal powder made of nickel with a high content of tungsten carbides evenly distributed in a solid matrix.

This powder has a matrix hardness of more than 60 HRC and tungsten carbide particle size which provides good resistance against abrasive and erosive wear.

Its composition is Ni-7Cr-6Fe + 60%WC, melting point varies from 1020℃ to 1115℃, the microhardness is 1900 HV, and the maximum operating temperature is approximately 700℃.

Powder consumption rate is 130gr/1 mm/dm2 for coating from 0.5mm to 2mm.

Additionally it is capable of grinding and the specific burner to be used is SuperJet S.

Features:

PE 1229 CTC/NiCrBSi is a highly advanced metal powder designed to deliver superior performance for various applications.

The powder is composed of carefully selected alloying elements that result in outstanding wear and corrosion resistance.

As such, it is perfect for use in demanding environments, such as chemical processing, oil and gas, and marine industries.

Furthermore, PE 1229 CTC/NiCrBSi offers an enviable combination of high hardness and toughness, allowing it to withstand heavy wear and impact.

This exceptional powder is also inherently resistant to corrosion and oxidation, making it highly suitable for corrosive environments. Additionally, it demonstrates good processability, with excellent flowability and deposition efficiency.

It can be used on a range of substrates, from steel to non-ferrous alloys, providing reliable solutions for various industrial applications.

In summary, PE 1229 CTC/NiCrBSi stands out for its exceptional wear and corrosion resistance, high hardness and toughness, processability, and versatility.

This highly advanced metal powder offers superior performance that can help to extend the service life of components, reduce maintenance costs, and improve equipment performance.

Applications:

CTC/NiBSi Powder is the perfect solution for earth moving equipment, cast tungsten carbide / nickel alloy powder are blend powders for PTA welding.

PTA Powders for Plasma Arc Transfer Welding are ideal for oil sand and lignite surface mining equipment, down hole tools, and other heavy-duty applications.

Protective coatings for conveyor screws, clay mixers, sand and grit mixers, turbine vanes, wire-drawing drums, fan blades, pump screws, etc.

The PE1229 PTA Powder is made using CTC/NiCrBSi, guaranteeing a hardness of 2000HV0.1/60HRC and a CTC/Ni Matrix ratio of 60/40. It comes in 25kg/drum, 50kg/drum packaging and is available in quantities of 50kgs, with a price of $45-50.0/kgs.

It has an ISO9001:2015 certification and delivery time of 7-10days.

The supply ability is 10tons/Month and payment is accepted via T/T at sight.

Customization:

CTC/NiCrBSi PTA Powder PE1229

Brand Name: CTC/NiCrBSi PTA Powder

Model Number: PE1229

Place of Origin: China

Certification: ISO9001:2015

Minimum Order Quantity: 50kgs

Price: $45-50.0/kgs

Packaging Details: 50kgs/Drum

Delivery Time: 7-10days

Payment Terms: T/T at sight

Supply Ability: 10tons/Month

Application: Oil Sand And Lignite Surface Mining Equipment,down Hole Tools , Earth Moving Equipment

Product Name: PTA Powder PE1229

Hardness of CTC/Ni Matrix: 2000HV0.1/60HRC

Manufacturing : Blending

Packaging: 25kg/drum,50kg/drum

CTC/NiBSi Powder for Oil sand and lignite surface mining equipment

CTC/NiBSi Powder for earth moving equipment

Cast Tungsten Carbide / Nickel alloy Powder are blend powders for PTA welding.

Support and Services:

PTA Powder offers technical support and services to help customers solve technical problems quickly and easily.

Our technical support team is available 24/7 to answer any questions or issues you may have.

We provide technical support by phone, email, or online chat. If you need help with installation, configuration, troubleshooting, or anything else related to our product, our team of experts is here to help.

We also provide software and firmware updates, as well as periodic maintenance and repair services.

Packing and Shipping:

Packaging and Shipping

According to package requirement of custome,Our packing can be bottles,drums,cartons in every possible way to shipping.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!