Product Description:

Product Summary:

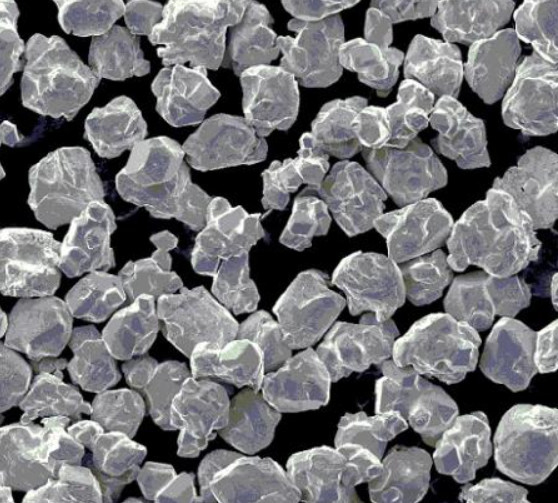

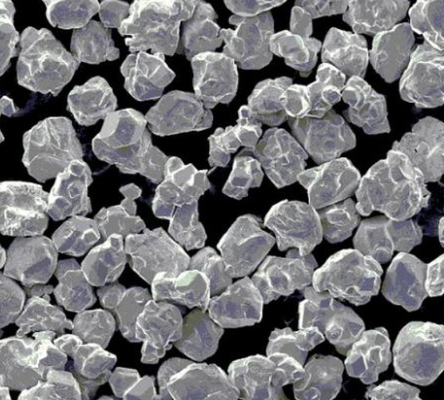

The Cast Tungsten Carbide Powder offered is a high-quality material known for its exceptional properties, making it a sought-after choice in various industries. This product features a density of 15.63 G/cm3, confirming its robust nature and suitability for demanding applications.

Composed primarily of tungsten carbide, this fused tungsten carbide powder is renowned for its superior hardness and wear resistance. The addition of cobalt enhances its toughness and overall performance, ensuring longevity and reliability in use.

One of the standout characteristics of this product is its impressive fracture toughness, exceeding 4.5MPa.m1/2. This attribute speaks to its durability and ability to withstand high-stress environments, making it an ideal material for critical components and wear-resistant coatings.

With a melting point of 2,870°C, this fused tungsten carbide powder exhibits exceptional thermal stability, allowing it to maintain its integrity even under extreme temperature conditions. This high melting point further contributes to its suitability for applications requiring heat resistance and thermal endurance.

In summary, the Cast Tungsten Carbide Powder stands out for its remarkable properties, including its high density, excellent fracture toughness, and impressive melting point. These attributes make it a reliable and versatile material for a wide range of industrial applications, where durability, wear resistance, and thermal stability are paramount.

Features:

-

Product Name: Cast Tungsten Carbide Powder

-

Particle Size: 1-10 Microns

-

Melting Point: 2,870°C

-

Fracture Toughness: >4.5MPa.m1/2

-

Density: 15.63 G/cm3

-

Classification: Carbide, Tungsten-based (CTC)

Technical Parameters:

|

Parameter

|

Value

|

|

Applications

|

Used In The Production Of Cutting Tools, Wear-resistant Coatings, And High-temperature Components

|

|

Melting Point

|

2,870°C

|

|

Classification

|

Carbide, Tungsten-based (CTC)

|

|

Appearance

|

Gray To Black Powder

|

|

Fracture Toughness

|

>4.5MPa.m1/2

|

|

Particle Size

|

1-10 Microns

|

|

Chemistry

|

W2C-WC

|

|

Boiling Point

|

6,000°C

|

|

Impact Toughness

|

>6.0J/cm2

|

|

Character

|

High Melting Point

|

Applications:

BODA Cast Tungsten Carbide Powder is a high-quality product designed for various industrial applications. With its fine particle size ranging from 1 to 10 microns, this tungsten carbide powder is ideal for a wide range of use cases.

One of the key application occasions for this product is in the manufacturing of cutting tools. The fine particles make it suitable for producing sharp and durable cutting edges for tools used in machining, woodworking, and metalworking industries. The high density of 15.63 G/cm3 ensures that the tools made from this powder have excellent wear resistance and long operational life.

Another important scenario where BODA Cast Tungsten Carbide Powder excels is in the production of wear-resistant components. Industries such as mining, oil and gas, and construction benefit from the superior hardness and toughness of tungsten carbide. This powder can be used to create parts that can withstand harsh conditions and extended use without losing their structural integrity.

Moreover, the product is also suitable for thermal spray applications. The ability of tungsten carbide to withstand high temperatures, with a boiling point of 6,000°C, makes it an excellent choice for coating surfaces that are exposed to extreme heat or abrasive wear. The powder can be used to create protective coatings on components in aerospace, automotive, and energy sectors.

For those looking to enhance their products with tungsten carbide properties, the BODA Cast Tungsten Carbide Powder offers a reliable solution. The product is classified as Tungsten-based Carbide (CTC) and is ISO9001:2015 certified, ensuring consistent quality and performance. With a negotiable minimum order quantity, pricing between $42-50 per kg, and flexible payment terms, customers can easily access this premium material.

In terms of packaging, the powder is available in 50kg and 25kg steel drums, providing convenience and protection during transportation and storage. The supply ability of 30 tons per month guarantees a steady source of this essential material for your manufacturing needs.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!