Product Description:

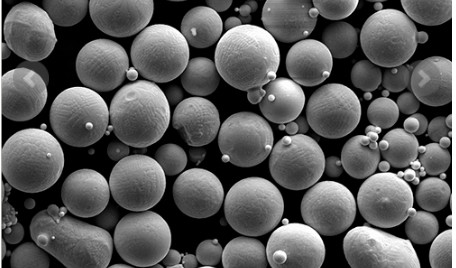

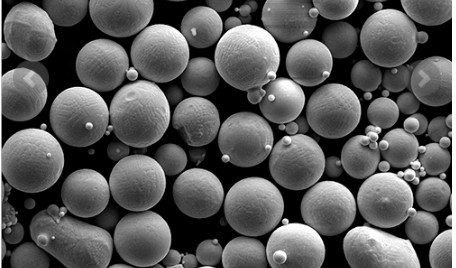

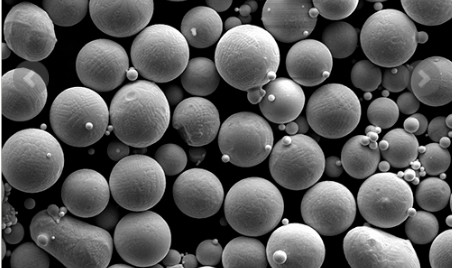

The Cast Tungsten Carbide Powder is a cutting-edge product in the realm of industrial materials. Known for its exceptional chemistry of W2C-WC, this powder is a blend of tungsten carbide and cobalt, offering unparalleled strength and durability. With a high melting point, this product is designed to withstand extreme temperatures and harsh conditions, making it ideal for a wide range of applications.

One of the key characteristics of this product is its impressive fracture toughness, measuring at over 4.5MPa.m1/2. This attribute ensures that the powder can resist cracking and breaking under pressure, providing long-lasting performance and reliability.

Classified as Carbide, Tungsten-based (CTC), this powder is recognized for its superior quality and composition. The fusion of tungsten carbide and cobalt results in a potent material that is highly sought after in various industries.

When it comes to particle size, the Cast Tungsten Carbide Powder boasts a fine range of 1-10 microns. This optimal size ensures uniformity in applications and allows for precise and controlled usage of the powder.

Whether you are in the manufacturing, mining, or construction sector, this tungsten carbide dust is a versatile and valuable asset to have in your arsenal. Its robust nature and exceptional properties make it a top choice for cutting, drilling, and wear-resistant applications.

For those in need of a reliable and high-performing material, the Cast Tungsten Carbide Powder is the ultimate solution. Its fusion of tungsten carbide and cobalt, along with its high melting point and superior fracture toughness, sets it apart as a premium choice for demanding industrial needs.

Features:

-

Product Name: Cast Tungsten Carbide Powder

-

Particle Size: 1-10 Microns

-

Color: Gray With Metallic Luster

-

Material: Tungsten Carbide

-

Fracture Toughness: >4.5MPa.m1/2

-

Classification: Carbide, Tungsten-based (CTC)

Technical Parameters:

|

Density

|

15.63 g/cm3

|

|

Impact Toughness

|

>6.0 J/cm2

|

|

Classification

|

Carbide, Tungsten-based (CTC)

|

|

Applications

|

Used In The Production Of Cutting Tools, Wear-resistant Coatings, And High-temperature Components

|

|

Fracture Toughness

|

>4.5 MPa.m1/2

|

|

Character

|

High Melting Point

|

|

Color

|

Gray With Metallic Luster

|

|

Powder Type

|

Sintered & Crushed

|

|

Particle Size

|

1-10 Microns

|

|

Melting Point

|

2,870°C

|

Applications:

The BODA Cast Tungsten Carbide Powder is a high-quality product suitable for a wide range of product application occasions and scenarios due to its exceptional attributes.

With its certification under ISO9001:2015, customers can trust in the quality and consistency of this product. The minimum order quantity is negotiable, making it accessible to various businesses. Priced between $42-50 per kilogram, this product offers excellent value for its quality.

The packaging details include 50kg or 25kg steel drums, providing convenience and flexibility in handling and storage. Delivery time and payment terms are also negotiable, catering to the specific needs of customers.

With a supply ability of 30 tons per month, businesses can rely on a steady source of this high-grade cast tungsten carbide powder. The product comes in a distinctive gray color with a metallic luster, adding a premium touch to its appearance.

The powder type is sintered and crushed, ensuring uniformity and reliability in performance. The particle size ranges from 1 to 10 microns, making it suitable for a variety of applications that require fine particles.

Chemically composed of W2C-WC, this product exhibits excellent properties that meet the requirements of different industries. With a high melting point of 2,870°C, it offers durability and stability under extreme conditions.

Product application occasions and scenarios for the BODA Cast Tungsten Carbide Powder include the manufacturing of cutting tools, wear-resistant components, thermal spray coatings, and more. Its versatility and quality make it an ideal choice for industries that demand precision and performance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!