Product Description:

The Cast Tungsten Carbide Powder is a premium product known for its exceptional quality and performance in various industrial applications. This product is characterized by its high hardness and superior wear resistance, making it an ideal choice for demanding environments where durability is essential.

With an electrical conductivity of 0.12% IACS, this Cast Tungsten Carbide Powder offers reliable electrical properties, ensuring efficient performance in electrical applications. Its thermal stability is another key feature, with the product remaining stable up to an impressive temperature of 1400°C, providing excellent heat resistance in high-temperature environments.

One of the standout attributes of the Cast Tungsten Carbide Powder is its impressive compressive strength of 3500 MPa, making it highly resistant to deformation under pressure. This strength contributes to the product's exceptional durability and longevity, ensuring reliable performance over extended periods.

Manufactured from high-quality tungsten carbide material, this product is designed to meet the highest standards of quality and reliability. The use of tungsten carbide ensures the product's exceptional hardness and wear resistance, making it a reliable choice for applications requiring superior strength and durability.

The Cast Tungsten Carbide Powder is a type of fused tungsten carbide powder that offers exceptional performance characteristics for a wide range of industrial applications. Its macro tungsten carbide powder composition provides enhanced properties, making it suitable for demanding applications where strength and wear resistance are critical.

Features:

-

Product Name: Cast Tungsten Carbide Powder

-

Chemical Formula: WC

-

Material: Tungsten Carbide

-

Impact Toughness: >6.0J/cm

2

-

Process: Laser Cladding, Arc Welding, PTA

-

Compressive Strength: 3500 MPa

Technical Parameters:

|

Process

|

Laser Cladding, Arc Welding, PTA

|

|

Application

|

Industry, hardfacing, paper Rolls, coating

|

|

Chemical Formula

|

WC

|

|

Impact Toughness

|

>6.0J/cm2

|

|

Advantages

|

High Hardness And High Wear Resistant

|

|

Chemical Resistance

|

Highly Resistant To Acids And Alkalis

|

|

Thermal Stability

|

Stable Up To 1400°C

|

|

Particle Size

|

1-10 Microns

|

|

Classification

|

Carbide, Tungsten-based (CTC)

|

|

Bending Strength

|

>3000MPa

|

Applications:

BODA's Cast Tungsten Carbide Powder is a versatile product that finds application in a wide range of industries and scenarios. This high-quality product is certified under ISO9001:2015, ensuring its adherence to international quality standards.

The product is available for purchase with a negotiable minimum order quantity and is priced competitively at $42-50 per kilogram. It comes in two convenient packaging options: 50kg/Steel Drum and 25kg/Steel Drum, catering to different volume requirements.

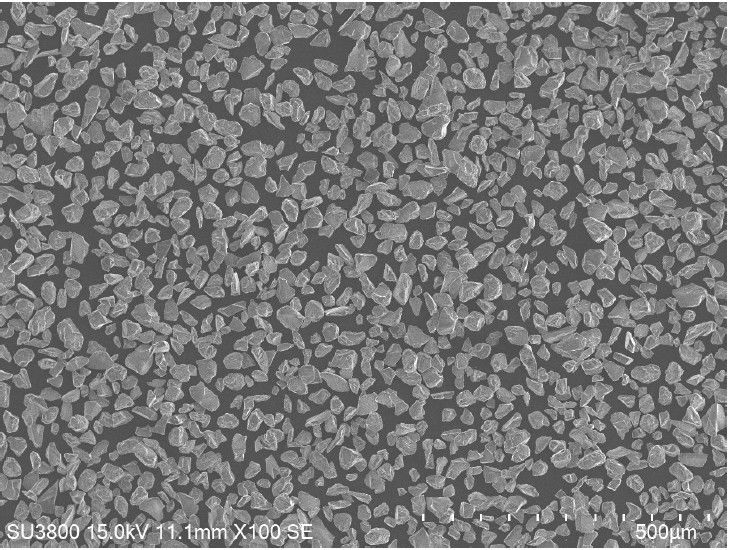

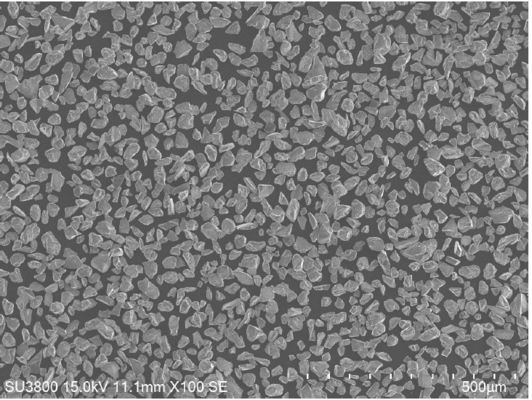

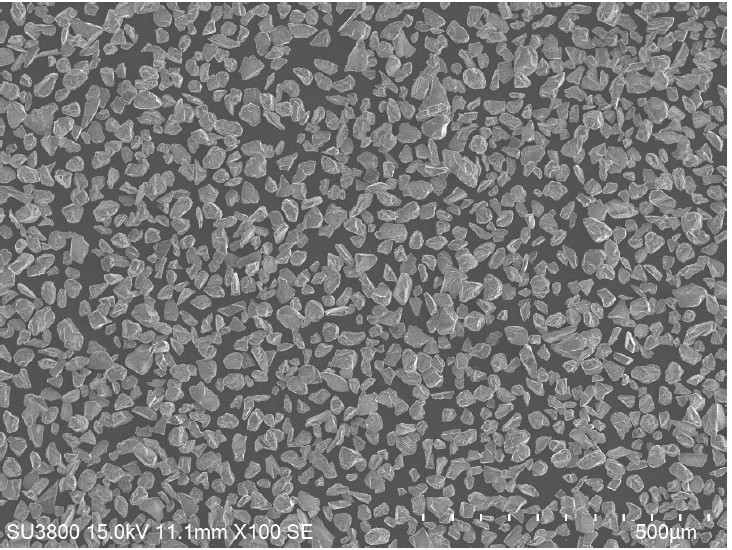

With a supply ability of 30 tons per month, BODA's Cast Tungsten Carbide Powder is suitable for various applications including hardfacing, paper rolls, and coating processes. The particle size ranges from 1 to 10 microns, making it ideal for precision applications.

One of the key attributes of this product is its high fracture toughness (>4.5MPa.m1/2), ensuring durability and reliability in demanding environments. The chemical formula WC signifies the product's composition of tungsten carbide and cobalt.

Cast Tungsten Carbide Powder can be utilized in a variety of processes such as laser cladding, arc welding, and PTA, offering flexibility in application methods. Its unique properties make it suitable for industries requiring wear-resistant materials and high-performance coatings.

Whether you are in the manufacturing, mining, or engineering sector, BODA's Cast Tungsten Carbide Powder is a valuable material for enhancing the durability and performance of your products. Contact us today to discuss your requirements and explore the possibilities with fused tungsten carbide powder.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!