Product Description:

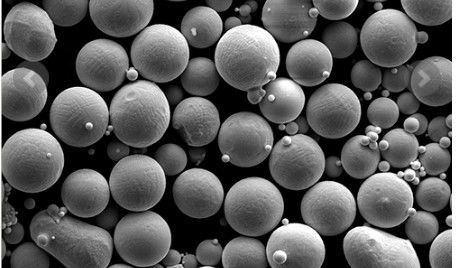

The Cast Tungsten Carbide Powder is a high-quality product known for its exceptional properties and wide range of applications. Made from fused tungsten carbide powder, this product offers superior performance in various industries.

Chemical Resistance: This tungsten carbide dust is highly resistant to acids and alkalis, making it ideal for use in corrosive environments where other materials may deteriorate.

Electrical Conductivity: With an electrical conductivity of 0.12% IACS, this tungsten carbide dust is suitable for applications where electrical conductivity is a critical factor.

Impact Toughness: The impact toughness of this product is greater than 6.0J/cm2, ensuring that it can withstand high-impact applications and provide long-lasting durability.

Oxidation Temperature: With an oxidation temperature exceeding 1000℃, this fused tungsten carbide powder is capable of withstanding high temperatures without losing its properties.

Bending Strength: The bending strength of this tungsten carbide dust is greater than 3000MPa, making it a reliable and sturdy material for applications that require high strength and durability.

Overall, the Cast Tungsten Carbide Powder is a versatile and reliable product that offers exceptional chemical resistance, electrical conductivity, impact toughness, oxidation resistance, and bending strength. Its high-quality properties make it a preferred choice for various industrial applications.

Features:

-

Product Name: Cast Tungsten Carbide Powder

-

Chemical Formula: WC

-

Chemical Resistance: Highly Resistant To Acids And Alkalis

-

Particle Size: 1-10 Microns

-

Impact Toughness: >6.0J/cm2

-

Oxidation Temperature: >1000℃

Technical Parameters:

|

Technical Parameter

|

Value

|

|

Process

|

Laser Cladding, Arc Welding, PTA

|

|

Material

|

Tungsten Carbide

|

|

Particle Size

|

1-10 Microns

|

|

Bending Strength

|

>3000MPa

|

|

Thermal Stability

|

Stable Up To 1400°C

|

|

Chemical Formula

|

WC

|

|

Advantages

|

High Hardness And High Wear Resistant

|

|

Compressive Strength

|

3500 MPa

|

|

Application

|

Industry, hardfacing, paper Rolls, coating

|

|

Impact Toughness

|

>6.0J/cm2

|

Applications:

The versatility of the Cast Tungsten Carbide Powder makes it ideal for numerous occasions and scenarios. Its fine particle size ranging from 1 to 10 microns allows for precise applications in processes such as laser cladding, arc welding, and PTA.

One of the key attributes of this product is its excellent impact toughness, exceeding 6.0J/cm2. This makes it a preferred choice for applications requiring high resistance to wear and impact, providing long-lasting durability in challenging environments.

With a low electrical conductivity of 0.12% IACS, the Cast Tungsten Carbide Powder is also suitable for electrical applications where minimal conductivity is required.

The packaging details of 50kg/Steel Drum or 25kg/Steel Drum offer convenience and flexibility for handling and storage, catering to different customer needs and preferences.

Customers can benefit from the negotiable minimum order quantity, price range of $42-50 per kilogram, and flexible delivery times and payment terms, ensuring a tailored and seamless purchasing experience.

With a supply ability of 30 tons per month, the BODA Cast Tungsten Carbide Powder ensures a steady and reliable source of this essential material for various manufacturing processes.

In conclusion, whether it's for applications requiring tungsten carbide and cobalt materials, tungsten carbide dust, or specifically Cast Tungsten Carbide Powder, this product offers exceptional quality, performance, and versatility to meet diverse industrial needs.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!