Product Description:

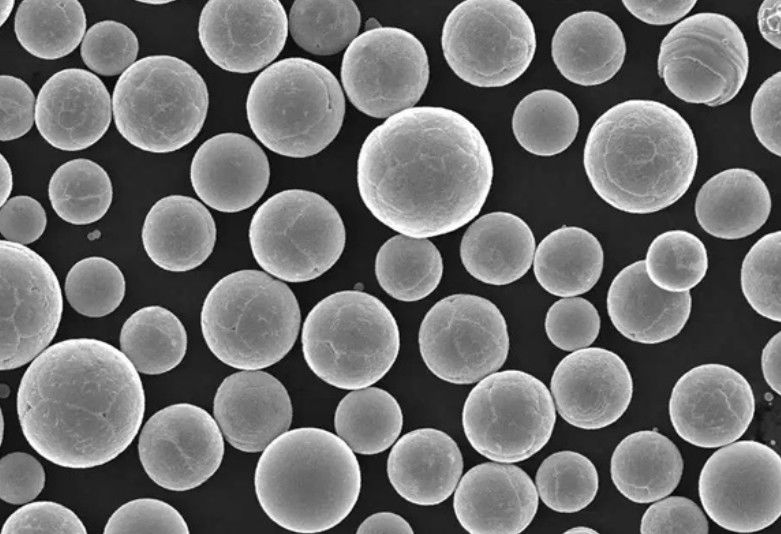

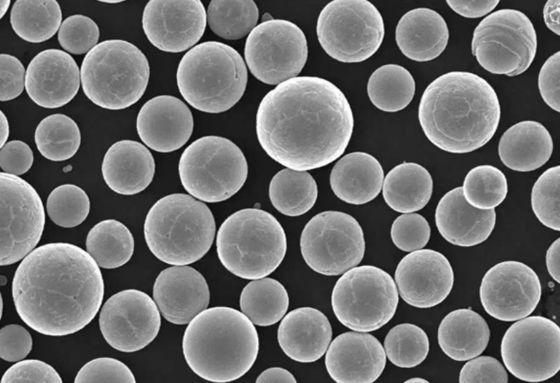

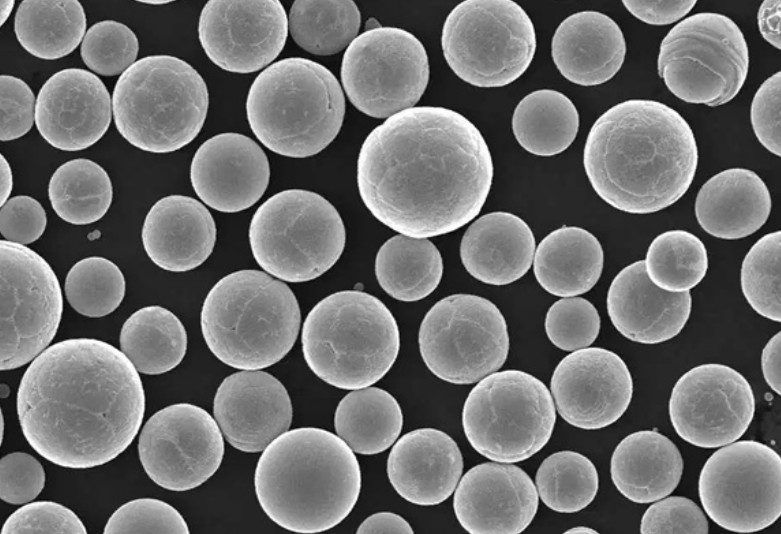

Cast Tungsten Carbide Powder is a high-quality material widely used in various industrial applications due to its exceptional hardness, wear resistance, and chemical stability. Classified as a carbide and tungsten-based (CTC) product, this powder primarily consists of tungsten carbide (WC) combined with metallic binders such as cobalt (Co), nickel (Ni), and iron (Fe), among other elements. The unique chemical composition of this powder ensures excellent performance in demanding environments, making it an essential component in the manufacture of cutting tools, wear parts, and other precision instruments.

The chemical composition of Cast Tungsten Carbide Powder is meticulously controlled to include tungsten carbide (WC) as the main constituent, along with cobalt (Co), nickel (Ni), and iron (Fe) as binder metals. This combination not only enhances the mechanical properties but also contributes to the powder's toughness and durability. The presence of cobalt is particularly important because it acts as a binder phase that holds the tungsten carbide grains together, thereby improving the overall strength and impact resistance of the final product. Nickel and iron may also be added in small quantities to tailor the powder's characteristics for specific applications.

One of the standout features of this Macro Tungsten Carbide Powder is its exceptionally high purity level, which is guaranteed to be ≥ 99.5%. This high degree of purity ensures minimal impurities, which could otherwise compromise the powder's performance and reliability. As a result, products manufactured from this powder exhibit superior hardness and wear resistance, essential for maintaining precision and longevity in industrial tools and components.

The hardness of the Cast Tungsten Carbide Powder is another critical attribute, with a value of ≥ 1600 HV (Vickers Hardness). This remarkable hardness makes it one of the hardest materials available, enabling it to withstand extreme wear and abrasion during machining, drilling, and cutting operations. The high hardness also contributes to the powder’s resistance to deformation and structural failure under high-stress conditions, making it ideal for use in demanding applications such as mining, metalworking, and manufacturing of wear-resistant parts.

Proper storage of this tungsten carbide and cobalt powder is essential to maintain its quality and performance. It is recommended to keep the powder in a dry, sealed container to prevent exposure to moisture and contaminants that could degrade its properties. Maintaining a controlled storage environment helps preserve the powder’s chemical integrity and prevents any potential oxidation or corrosion of the metallic binder phase. Ensuring these storage conditions is crucial for delivering consistent results in subsequent processing and end-use applications.

During handling and processing, it is important to be aware of the presence of tungsten carbide dust, which can be generated during grinding, milling, or other mechanical operations. Tungsten carbide dust requires careful management due to its fine particulate nature and potential health hazards if inhaled. Appropriate safety measures, such as the use of respiratory protection and effective ventilation systems, should be employed to minimize exposure and ensure a safe working environment.

In summary, Cast Tungsten Carbide Powder is a superior-grade material characterized by its chemical composition of WC, Co, Ni, Fe, and other elements, high purity (≥ 99.5%), outstanding hardness (≥ 1600 HV), and classification as a carbide, tungsten-based (CTC) product. Its exceptional properties make it indispensable for applications requiring extreme hardness, wear resistance, and toughness. Proper storage in dry, sealed containers and careful handling of tungsten carbide dust are essential to maintain its quality and ensure safety. This Macro Tungsten Carbide Powder stands out as a reliable choice for manufacturers and industries seeking durable and high-performance tungsten carbide and cobalt materials.

Features:

-

Product Name: Cast Tungsten Carbide Powder

-

Classification: Carbide, Tungsten-based (CTC)

-

High purity with ≥ 99.5% tungsten carbide and cobalt content

-

Melting Point: 2,870°C, suitable for high-temperature applications

-

Specific Surface Area: 5 - 15 M²/g for enhanced reactivity

-

Fused tungsten carbide powder ensuring uniform particle distribution

-

Storage Condition: Keep in dry, sealed container to maintain quality

Technical Parameters:

|

Classification

|

Carbide, Tungsten-based (CTC)

|

|

Color

|

Gray With Metallic Luster

|

|

Chemical Composition

|

WC, Co, Ni, Fe, Etc.

|

|

Dimensions

|

20-30mesh, 40-60mesh, 100-140mesh

|

|

Storage Condition

|

Keep In Dry, Sealed Container

|

|

Compressive Strength

|

>3000MPa

|

|

Hardness

|

≥ 1600 HV

|

|

Particle Size

|

1-10 Microns

|

|

Specific Surface Area

|

5 - 15 M²/g

|

|

Character

|

High Hardness And High Wear Resistant

|

Applications:

BODA Cast Tungsten Carbide Powder, certified under ISO9001:2015, is widely recognized for its superior quality and exceptional performance in various industrial applications. With a chemical composition primarily of WC (Tungsten Carbide) and a purity level of ≥ 99.5%, this powder boasts high hardness and excellent wear resistance, making it an ideal material for manufacturing durable and long-lasting tools and components.

One of the primary application occasions for BODA Cast Tungsten Carbide Powder is in the production of cutting tools, mining bits, drilling equipment, and wear parts. The high hardness and wear resistance properties of tungsten carbide and cobalt composites ensure optimal performance under extreme conditions, improving the lifespan and reliability of these tools. The powder’s fine particle size, ranging from 1 to 10 microns, enables precise control over sintering and molding processes, which is essential for high-quality fused tungsten carbide powder products.

In manufacturing scenarios where toughness and abrasion resistance are critical, the BODA tungsten carbide dust is utilized extensively. Its use in powder metallurgy allows manufacturers to produce components that can withstand harsh environments, such as in the automotive, aerospace, and heavy machinery sectors. The powder’s consistent purity and particle size distribution help in achieving uniformity and strength in the final product, which is crucial for performance-driven industries.

Packaging is designed to maintain the powder’s integrity, with options including 50kg and 25kg steel drums, ensuring safe and dry storage conditions. It is essential to keep the tungsten carbide powder in a sealed container to prevent moisture absorption, which could adversely affect its properties. BODA offers flexible negotiation on minimum order quantities, pricing between $42 to $50 per kilogram, and delivery times, catering to the specific needs of different clients.

With a supply capacity of 30 tons per month, BODA guarantees a reliable and steady supply for large-scale industrial demands. Payment terms are negotiable, providing ease and convenience for global buyers. Overall, BODA Cast Tungsten Carbide Powder is a premium material choice for industries seeking high-performance tungsten carbide and cobalt products, fused tungsten carbide powder, and tungsten carbide dust for advanced manufacturing processes.

Customization:

Our Cast Tungsten Carbide Powder, branded under BODA, offers exceptional quality with a purity of ≥ 99.5% and particle size ranging from 1 to 10 microns. The product is certified by ISO9001:2015, ensuring reliable performance and consistency for your industrial needs.

The chemical composition of our Cast Tungsten Carbide Powder includes WC, Co, Ni, Fe, and other elements, providing superior hardness and wear resistance. With a melting point of 2,870°C, it is ideal for high-temperature applications.

We provide flexible product customization services including negotiable minimum order quantities and delivery times to suit your project requirements. Pricing for the Cast Tungsten Carbide Powder ranges from $42 to $50 per kilogram.

Packaging options include 50kg steel drums and 25kg steel drums, ensuring safe storage and shipment. Please store the Cast Tungsten Carbide Powder in a dry, sealed container to maintain its quality.

Our supply ability is up to 30 tons per month, and payment terms are negotiable to accommodate your business needs. Trust BODA for premium Cast Tungsten Carbide Powder tailored to your specifications.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!