Product Description:

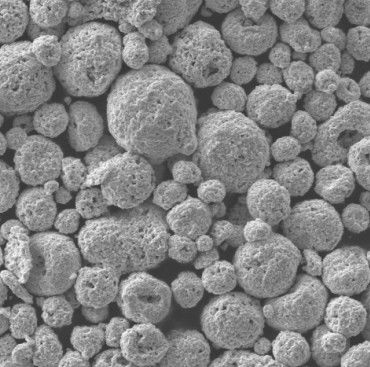

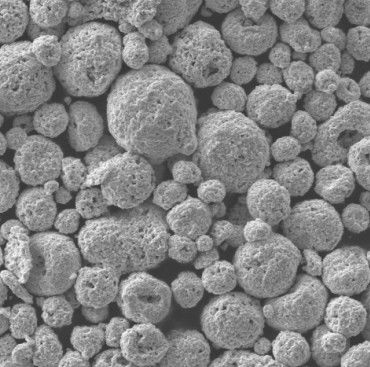

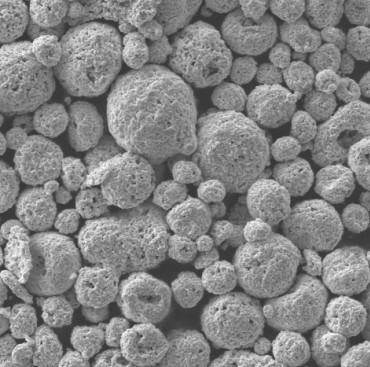

Cast Tungsten Carbide Powder is a high-performance material widely used in various industrial applications due to its exceptional hardness, durability, and resistance to wear and corrosion. This powder is produced through a specialized casting process that ensures uniform particle size distribution and superior quality. Available in multiple dimensions including 20-30 mesh, 40-60 mesh, and 100-140 mesh, the Cast Tungsten Carbide Powder offers versatility for different manufacturing needs and precision engineering applications.

One of the most notable characteristics of this product is its impressive melting point of 2,870°C, which makes it highly suitable for high-temperature environments and processes. This extreme melting point ensures that the fused tungsten carbide powder maintains its structural integrity even under intense heat, making it indispensable in industries such as aerospace, automotive, tooling, and mining where materials are often subjected to harsh conditions.

The Cast Tungsten Carbide Powder exhibits a specific surface area ranging from 5 to 15 m²/g, which contributes to its excellent reactivity and bonding properties when used in composite materials or coatings. This specific surface area range is optimal for achieving a balance between surface activity and particle stability, allowing for efficient sintering and enhanced mechanical properties in the final product.

Color-wise, the powder presents a distinctive gray hue with a metallic luster, reflecting its high purity and quality. This characteristic appearance not only indicates the presence of tungsten carbide but also serves as a visual confirmation of the product's consistency and manufacturing precision. The metallic luster is a hallmark of the fused tungsten carbide powder's refined structure and high density.

Proper storage of the Cast Tungsten Carbide Powder is crucial to maintaining its quality and performance. It is recommended to keep the powder in a dry, sealed container to prevent moisture absorption and contamination. Moisture can adversely affect the powder's properties, leading to reduced effectiveness in applications. Therefore, adhering to the storage condition of keeping the powder dry and sealed ensures long-term stability and reliability.

Among the variants of tungsten carbide powders, Macro Tungsten Carbide Powder stands out due to its larger particle size and enhanced mechanical strength. This makes Macro Tungsten Carbide Powder ideal for applications requiring robust wear resistance and impact toughness. The Cast Tungsten Carbide Powder, available in macro sizes such as 20-30 mesh and 40-60 mesh, provides excellent performance in cutting tools, wear parts, and other components exposed to abrasive environments.

In summary, Cast Tungsten Carbide Powder is a premium material characterized by its diverse particle size options, extremely high melting point, significant specific surface area, and metallic gray color. Its production as fused tungsten carbide powder ensures uniformity and quality, making it a reliable choice for demanding industrial applications. The availability of Macro Tungsten Carbide Powder sizes adds to the product's versatility, catering to a wide range of manufacturing and engineering requirements. When stored properly in dry, sealed containers, this powder maintains its superior properties, ensuring optimal performance and longevity in all its uses.

Features:

-

Product Name: Cast Tungsten Carbide Powder

-

Material: Tungsten Carbide

-

Compressive Strength: >3000MPa

-

Purity: ≥ 99.5%

-

Character: High Hardness And High Wear Resistant

-

Chemical Composition: WC, Co, Ni, Fe, Etc.

-

Contains fused tungsten carbide powder for enhanced durability

-

Available as Macro Tungsten Carbide Powder for various industrial applications

-

Macro Tungsten Carbide Powder ensures consistent quality and performance

Technical Parameters:

|

Hardness

|

≥ 1600 HV

|

|

Classification

|

Carbide, Tungsten-based (CTC)

|

|

Color

|

Gray With Metallic Luster

|

|

Specific Surface Area

|

5 - 15 M²/g

|

|

Chemical Composition

|

WC (Tungsten Carbide), Co, Ni, Fe, Etc.

|

|

Compressive Strength

|

>3000 MPa

|

|

Material

|

Tungsten Carbide

|

|

Purity

|

≥ 99.5%

|

|

Dimensions

|

20-30 mesh, 40-60 mesh, 100-140 mesh

|

Applications:

The BODA Cast Tungsten Carbide Powder, model number Cast Tungsten Carbide, is a high-quality material widely used in various industrial applications due to its exceptional hardness and durability. Certified by ISO9001:2015, this product guarantees superior quality and consistency, making it ideal for demanding manufacturing processes. With a purity of ≥ 99.5% and a hardness rating of ≥ 1600 HV, it ensures excellent performance in wear-resistant and high-strength components.

This Macro Tungsten Carbide Powder is primarily composed of tungsten carbide (WC) combined with cobalt (Co), nickel (Ni), iron (Fe), and other elements, offering enhanced toughness and stability. Its unique chemical composition makes it suitable for producing cutting tools, mining equipment, drilling parts, and wear-resistant coatings. The presence of cobalt as a binder improves the powder’s mechanical properties, providing an optimal balance between hardness and impact resistance.

In manufacturing scenarios, BODA's cast tungsten carbide powder is extensively utilized in the production of inserts, dies, and molds used in metalworking, automotive, aerospace, and construction industries. It is particularly effective in applications that require resistance to abrasion, corrosion, and high temperatures. The powder can be sintered and molded into various shapes to meet specific engineering requirements.

Storage and handling of this tungsten carbide and cobalt powder are straightforward, as it should be kept in a dry, sealed container to maintain its purity and prevent contamination. BODA supplies the powder in packaging options of 50kg or 25kg steel drums, ensuring safe transportation and long-term storage. With a supply ability of 30 tons per month and negotiable minimum order quantities, delivery times, and payment terms, BODA provides flexible solutions tailored to customer needs.

Overall, the Cast Tungsten Carbide Powder by BODA is an ideal choice for industries seeking a reliable, high-performance material for tough applications involving wear resistance and mechanical strength. Whether used in the production of cutting tools, mining bits, or structural components, this tungsten carbide and cobalt powder delivers consistent results, helping manufacturers achieve enhanced efficiency and durability in their products.

Customization:

Our Cast Tungsten Carbide Powder, branded as BODA and model number Cast Tungsten Carbide, offers exceptional quality with a purity of ≥ 99.5%. Certified under ISO9001:2015, this product is designed to meet your specific needs in tungsten carbide and cobalt applications.

We provide customization services for various particle sizes ranging from 1-10 microns and dimensions including 20-30mesh, 40-60mesh, and 100-140mesh to suit different industrial requirements. Our chemical composition primarily consists of WC (Tungsten Carbide), ensuring high-performance fused tungsten carbide powder for your manufacturing processes.

The minimum order quantity is negotiable, allowing flexibility for your project scale. Packaging options include 50kg or 25kg steel drums to maintain product integrity during transport. We offer a supply ability of up to 30 tons per month, with delivery time and payment terms also negotiable to accommodate your schedule and financial preferences.

Choose BODA’s Cast Tungsten Carbide Powder for reliable quality and tailored solutions in carbide and tungsten-based (CTC) materials.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!