Product Description:

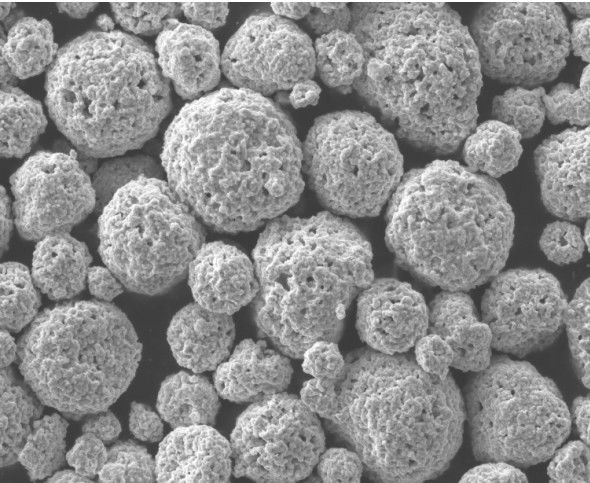

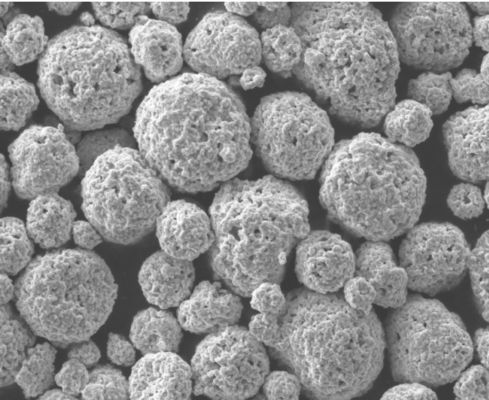

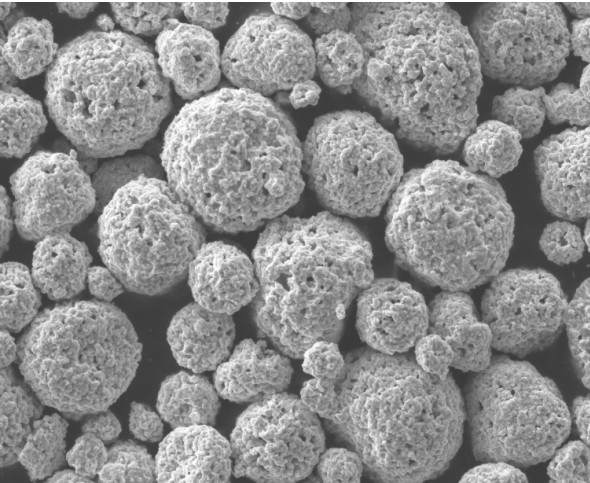

Cast Tungsten Carbide Powder is a high-quality material widely used in various industrial applications due to its exceptional hardness, durability, and resistance to wear and corrosion. Manufactured from premium tungsten carbide, this powder is available in multiple dimensions including 20-30 mesh, 40-60 mesh, and 100-140 mesh, providing versatility to meet different processing and manufacturing requirements. Each particle of the Macro Tungsten Carbide Powder exhibits a consistent size distribution, ensuring uniformity and reliability in its performance across a range of uses.

The primary material of this product, tungsten carbide, is renowned for its outstanding hardness, rated at ≥ 1600 HV, making it one of the hardest substances available. This superior hardness level contributes significantly to the powder's ability to enhance the wear resistance and longevity of tools and components in which it is incorporated. The cast tungsten carbide powder's robust structure allows it to withstand extreme mechanical stress, making it ideal for use in cutting tools, mining equipment, abrasives, and other demanding industrial processes.

Visually, the tungsten carbide dust exhibits a distinctive gray color with a metallic luster, a hallmark characteristic that not only indicates its purity but also its high-quality composition. This aesthetic quality is important for quality control and identification during manufacturing and application. The metallic sheen reflects the powder's dense and compact nature, which is essential for achieving optimal performance in sintering and other powder metallurgy processes.

Proper storage of the Macro Tungsten Carbide Powder is crucial to maintain its integrity and prevent contamination. It is recommended to keep the powder in a dry, sealed container to protect it from moisture and environmental pollutants that could degrade its quality. Maintaining these storage conditions ensures that the tungsten carbide dust remains stable, preserving its hardness and physical properties over time. This careful handling is especially important in environments where the powder may be exposed to varying temperatures and humidity levels.

The versatility of the cast tungsten carbide powder extends to its applications in the production of cutting inserts, dies, wear parts, and various coatings that require exceptional hardness and wear resistance. Its ability to enhance the mechanical properties of composites and alloys makes it an indispensable material in fields such as aerospace, automotive manufacturing, tooling, and electronics. Moreover, the powder's fine particle size options allow for precise control over the microstructure of the final products, enabling manufacturers to tailor properties to specific requirements.

In industrial environments where tungsten carbide dust is generated, it is important to handle the material with care due to its fine particulate nature. Proper safety measures should be implemented to minimize exposure and prevent inhalation, as tungsten carbide dust can pose health risks if not managed correctly. Utilizing appropriate ventilation, protective equipment, and dust collection systems helps ensure a safe working environment while benefiting from the superior properties of the tungsten carbide powder.

Overall, cast tungsten carbide powder represents a critical material for enhancing the performance and durability of a wide array of industrial products. Its exceptional hardness of ≥ 1600 HV, combined with its availability in multiple mesh sizes (20-30 mesh, 40-60 mesh, 100-140 mesh), and its characteristic gray color with metallic luster, makes it a preferred choice among manufacturers. By adhering to recommended storage conditions, the quality and effectiveness of the tungsten carbide dust can be preserved, ensuring consistent results in every application.

Features:

-

Product Name: Cast Tungsten Carbide Powder

-

Specific Surface Area: 5 - 15 M²/g

-

Chemical Composition: WC (Tungsten Carbide)

-

Character: High Hardness and High Wear Resistant

-

Hardness: ≥ 1600 HV

-

Compressive Strength: >3000 MPa

-

Contains Macro Tungsten Carbide Powder for enhanced durability

-

Includes tungsten carbide dust for improved material consistency

-

Produced using fused tungsten carbide powder technology

Technical Parameters:

|

Product Name

|

Cast Tungsten Carbide Powder

|

|

Material

|

Tungsten Carbide

|

|

Chemical Composition

|

WC (Tungsten Carbide), Co, Ni, Fe, Etc.

|

|

Particle Size

|

1-10 Microns

|

|

Hardness

|

≥ 1600 HV

|

|

Density

|

14.5 - 15.0 G/cm³

|

|

Melting Point

|

2,870°C

|

|

Color

|

Gray With Metallic Luster

|

|

Character

|

High Hardness And High Wear Resistant

|

|

Storage Condition

|

Keep In Dry, Sealed Container

|

Applications:

BODA's Cast Tungsten Carbide Powder, certified under ISO9001:2015, is a premium quality material designed to meet diverse industrial needs. With a purity level of ≥ 99.5% and a specific surface area ranging from 5 to 15 M²/g, this fused tungsten carbide powder offers exceptional hardness, wear resistance, and thermal stability. Available in various dimensions including 20-30 mesh, 40-60 mesh, and 100-140 mesh, it provides flexibility for different application requirements.

The Cast Tungsten Carbide Powder by BODA is widely used in manufacturing cutting tools, mining tools, and wear-resistant parts. Its superior physical and chemical properties make it ideal for producing drills, end mills, inserts, and other precision tooling components that demand high durability and performance. Industries such as mining, metalworking, and construction benefit significantly from the enhanced strength and longevity of products made with fused tungsten carbide powder.

In addition to tooling, this tungsten-based carbide (CTC) material is also utilized in wear parts for pumps, valves, and machinery components exposed to harsh environments. Its resistance to abrasion and corrosion extends equipment life, reducing downtime and maintenance costs. The product is also suitable for applications in the automotive and aerospace sectors where reliability under extreme conditions is critical.

BODA offers flexible ordering options with a negotiable minimum order quantity and supply ability of 30 tons per month. The pricing ranges between $42-50 per kilogram, making it a cost-effective choice without compromising quality. Packaging is available in 50kg or 25kg steel drums, ensuring safe and convenient transportation. Delivery time and payment terms are negotiable, allowing customization to meet customer needs.

Overall, BODA’s fused tungsten carbide powder stands out as a versatile, high-performance material essential for industries requiring robust and reliable carbide solutions. Its consistent quality, backed by ISO certification and stringent manufacturing standards, ensures that users receive a product capable of enhancing productivity and operational efficiency across multiple application scenarios.

Customization:

BODA offers customized product services for our Cast Tungsten Carbide Powder, model number Cast Tungsten Carbide, ensuring high-quality standards with ISO9001:2015 certification. Our Macro Tungsten Carbide Powder is meticulously formulated with a chemical composition including WC, Co, Ni, Fe, and other elements, providing exceptional purity of ≥ 99.5% and hardness of ≥ 1600 HV.

We specialize in tungsten carbide and cobalt powders with particle sizes ranging from 1 to 10 microns, classified as carbide, tungsten-based (CTC). Our supply ability reaches up to 30 tons per month, making us a reliable partner for your industrial needs.

The minimum order quantity is negotiable to accommodate your specific requirements, and pricing is competitively set between $42-50 per kilogram. Packaging options include 50kg and 25kg steel drums, ensuring safe and secure delivery.

Delivery time and payment terms are flexible and negotiable to fit your schedule and business preferences. Trust BODA for premium tungsten carbide and cobalt powders, tailored to meet your unique manufacturing demands.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!