Product Description:

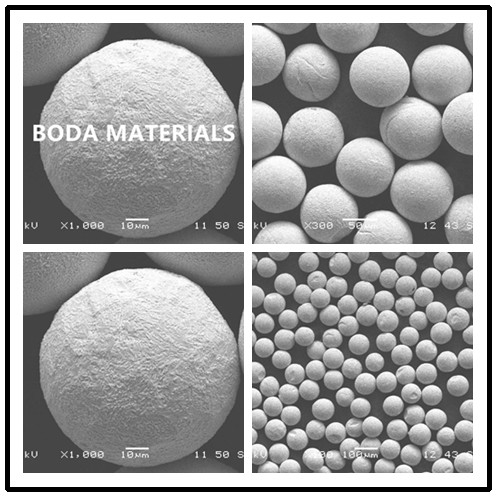

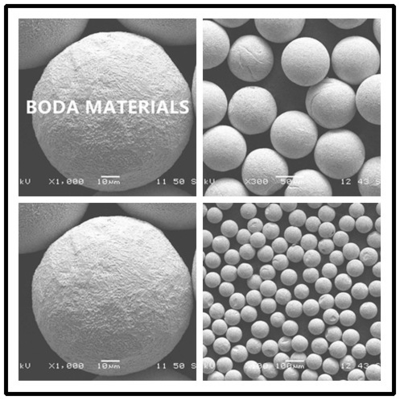

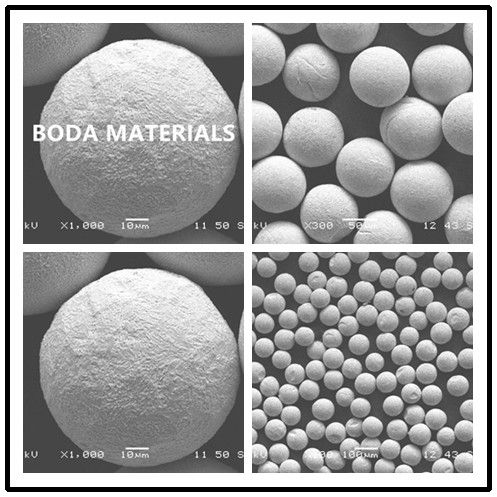

Spherical Fused Tungsten Carbides (CTC-S)

CTC-S are spheroidally shaped, two-phase tungsten carbide powders produced through a special melting process. This makes them the most wear resistant fused tungsten carbide products available on the market.

This materials are designed to be the hard phase constituent of a wear-resistant surface. Depending on the surfacing process, they can be blended with self-fluxing alloys or used a filler material for rods, wires, electrodes or infiltration applications.

Overlays containing CTC-S offer excellent abrasive wear resistance in harsh environments, combined with good impact resistance.

Features:

Spherical Cast Tungsten Carbide Powder offers exceptional features that make it a highly sought-after material for industrial applications. Its unique properties and superior performance make it stand out as a versatile and reliable choice.

The powder is carefully engineered to have spherical particle shapes, which enables improved flowability, packing density, and uniform distribution. This results in excellent consistency in coating and manufacturing processes and enhanced end-product quality.

It is produced using advanced refining techniques, resulting in a high-purity composition without any impurities or contaminants. This guarantees its reliability, stability, and consistent performance, meeting the stringent requirements of various industries.

The powder offers unparalleled hardness and wear resistance. This makes it ideal for applications where components are subjected to extreme conditions, such as abrasion, erosion, heat, and impact. It considerably extends their lifespan and provides cost-effective solutions.

It also has excellent thermal stability and high chemical inertness. This makes it suitable for components exposed to harsh temperatures and chemicals, respectively, and ensures long-lasting performance and minimal degradation.

Moreover, it offers incredible versatility and can be used as an additive or as a standalone material. Its properties can be tailored to meet specific applications by varying particle size, concentration, and coating.

Technical Parameters:

| Property |

Value |

| Machinability |

Good |

| Material |

Tungsten Carbide |

| Product Name |

Spherical Cast Tungsten Carbide |

| Shape |

Spherical |

| Manufacture |

Fused, Crushed And Plasma Densified |

| Hardness |

2700 – 3100 HV0.1 |

| Apparent Density |

9.0 – 11.0 G/cm3 |

Applications:

Spherical Cast Tungsten Carbide is an innovative cast tungsten carbide product from China. It is produced by a unique process of fusion, crushing and plasma densification, making it even tougher and more wear-resistant than traditional tungsten carbide. With its good machinability and hardness of 2700-3100 HV0.1, Spherical Cast Tungsten Carbide is an ideal choice for a wide range of applications, from heavy-duty industrial tools to precision medical instruments.

Spherical Cast Tungsten Carbide has a wide array of uses, such as for cutting tools, mining tools, and wear parts, and is also used for applications in aerospace, automotive, and medical industries. With a high-performance, cost-effective, and long-lasting product life, Spherical Cast Tungsten Carbide is one of the most popular materials used in today's manufacturing world.

Spherical Cast Tungsten Carbide is a unique product that offers the perfect combination of strength, toughness, and wear resistance. Its superior machinability and hardness make it an ideal choice for many applications. Whether it's for heavy-duty industrial tools, precision medical instruments, or wear parts, Spherical Cast Tungsten Carbide provides the perfect solution.

Support and Services:

We provide technical support and service for Spherical Cast Tungsten Carbide. Our service includes:

- Responding to customer inquiries in a timely fashion

- Providing professional advice and guidance

- Repairing and replacing faulty parts

- Troubleshooting any issues that arise

- Supplying spare parts and accessories

FAQ:

- Q: What is Spherical Cast Tungsten Carbide?

- A: Spherical Cast Tungsten Carbide is a high hardness and wear resistant alloy produced by sintering a mixture of tungsten carbide and cobalt powder.

- Q: What is the brand name of the product?

- A: The brand name of the product is Spherical Cast Tungsten Carbide.

- Q: Where is the Spherical Cast Tungsten Carbide produced?

- A: The Spherical Cast Tungsten Carbide is produced in China.

- Q: What are the advantages of Spherical Cast Tungsten Carbide?

- A: The advantages of Spherical Cast Tungsten Carbide are its high wear resistance, high hardness and its ability to withstand high temperatures.

- Q: What are the applications of Spherical Cast Tungsten Carbide?

- A: Spherical Cast Tungsten Carbide can be used in many industries, such as mining, aerospace, automotive and defense industries.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!